3 min read

Exploring the Types of Storage Tank Internal Floating Roofs

Concord Tank Corporation

Jul 18, 2023 1:00:00 PM

Storage tanks play a vital role in various industries, especially in the oil and gas industry, providing a means to store large quantities of liquids, including petroleum, chemicals, and water. To ensure the safe and efficient operation of these tanks, internal floating roofs (IFRs) are employed.

At Concord Tank Corporation, we specialize in storage tank repairs and maintenance, including the installation and upkeep of internal floating roofs. In this comprehensive guide, we will delve into the types of internal floating roofs available, their benefits, and considerations for choosing the right one for your storage tank.

1. What Are Internal Floating Roofs?

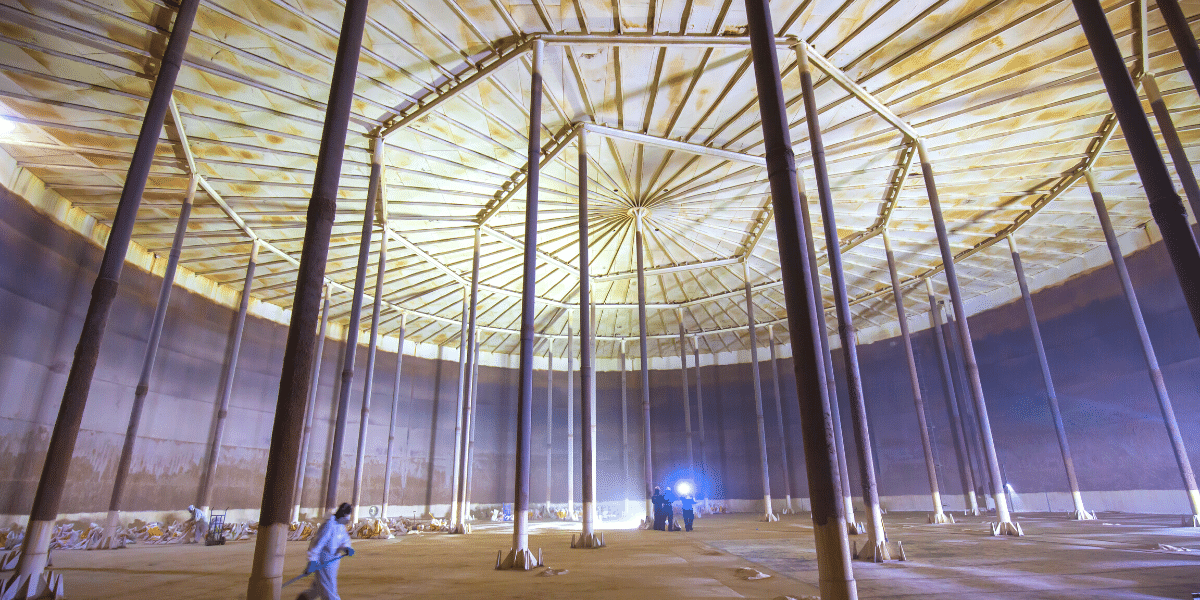

Internal floating roofs are a key component of storage tanks designed to reduce evaporation losses and emissions while maintaining product quality. These roofs "float" on the liquid surface within the tank, adjusting their position based on the product's volume. By covering the liquid surface, IFRs minimize the contact between the stored product and the atmosphere, thus mitigating vaporization.

2. Types of Internal Floating Roofs

Internal floating roofs (IFRs) come in various designs to suit different storage tank applications. The three main types of IFRs are steel, aluminum, and full contact. Each type offers distinct advantages and features that make them suitable for specific industry requirements. Whether you need durability, lightweight construction, or enhanced sealing capabilities, there is an internal floating roof solution to meet your needs. Let's dive deeper into each type to understand their unique benefits.

a. Steel IFRs

Steel internal floating roofs are widely used due to their durability and ability to withstand harsh environments. Constructed from steel components, these roofs offer exceptional resistance to corrosion and a long lifespan.

Steel IFRs come in different types, such as pontoon type and double deck type. Pontoon-type IFRs consist of a series of individual pontoons connected by a deck, providing stability and even distribution of weight. Double deck-type IFRs feature two decks, providing enhanced sealing and additional storage capacity.

b. Aluminum IFRs

Aluminum internal floating roofs are preferred when weight is a critical factor or when storing flammable or hazardous materials. Aluminum roofs offer lightweight construction, excellent corrosion resistance, and non-sparking properties, making them suitable for applications where safety is paramount. They are particularly common in the oil and gas industry and locations with strict fire safety regulations.

c. Full Contact IFRs

Full contact IFRs, also known as honeycomb IFRs, rest directly on the surface of the stored product, providing a complete seal. These roofs offer improved sealing capabilities, reducing emissions and evaporation to a minimum. Full contact IFRs are commonly used in industries that require strict vapor control, such as chemical storage facilities.

3. Considerations for Choosing an Internal Floating Roof

When selecting an internal floating roof (IFR) for your storage tank, several crucial factors should be taken into consideration: tank characteristics, environmental factors, and maintenance and repairs. These factors will influence the design and specifications, affect the performance and durability, and ensure the longevity and optimal functioning of the IFR.

a. Tank Characteristics

When selecting an internal floating roof, it's crucial to consider the characteristics of the storage tank. Factors such as tank size, shape, and the type of product being stored influence the choice of IFR. Tanks with irregular shapes may require customized IFR solutions, while tanks with varying product densities might necessitate specific design considerations.

b. Environmental Factors

Environmental conditions play a significant role in IFR selection. Factors like wind speed, temperature variations, and seismic activity can impact the performance and effectiveness of the internal floating roof. It is essential to assess these factors to ensure the chosen IFR can withstand and function optimally under the prevailing environmental conditions.

c. Maintenance and Repairs

Regular maintenance and inspections are crucial to ensure the proper functioning of internal floating roofs. Depending on the type of IFR, specific maintenance requirements and potential repairs may be necessary.

Trusting professional services like Concord Tank Corporation for routine maintenance and timely repairs is essential to extend the lifespan of your internal floating roof and ensure continued safe operation of your storage tank.

Conclusion

Internal floating roofs are an indispensable component of storage tanks, offering numerous benefits such as reduced evaporation losses, lower emissions, and improved product quality. Understanding the different types of IFRs available and considering factors such as tank characteristics, environmental conditions, and maintenance needs is crucial for choosing the right solution for your storage tank.

At Concord Tank Corproation, we specialize in storage tank repairs and maintenance, including the installation and maintenance of internal floating roofs. Contact us today to learn more about how we can assist you with your storage tank needs.

ABOUT CONCORD TANK

Concord Tank Corporation specializes in tank repairs and terminal maintenance. We help simplify and expedite your projects without sacrificing safety and quality. From initial decommissioning through to the final return to service, our experienced team can take care of your tank project needs. Our services include API 653 tank repairs, in-service leg pinning, terminal maintenance projects, storage tank cleaning, floating roof seal repairs, aluminum IFR installation, and more.